<News

Woven Label Washed Finish with White Print – Subtle Branding for Premium Apparel

Posted on 2025-09-28

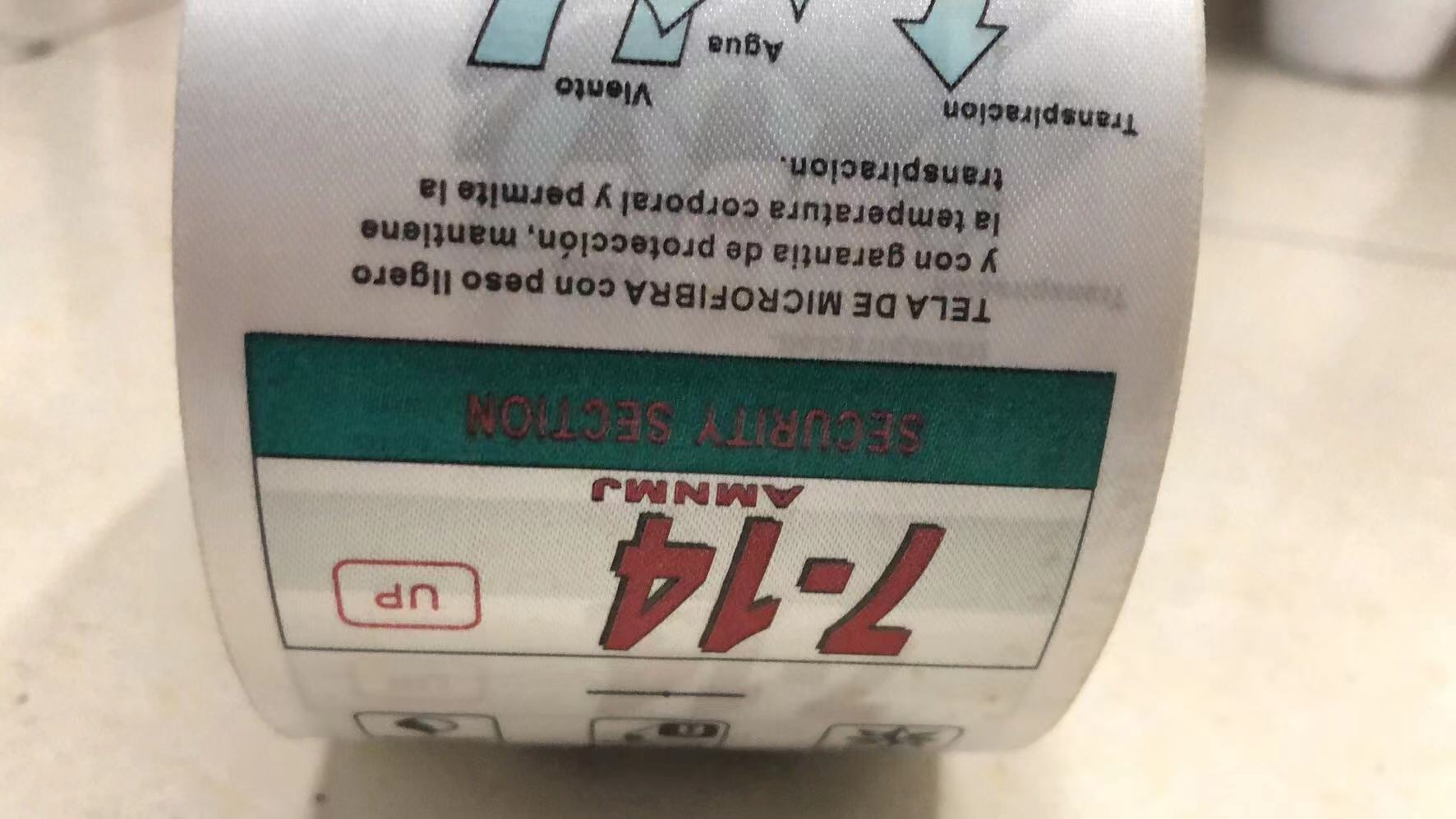

A closer look at the soft, lived-in texture of our woven labels — where minimalism meets enduring quality.

When a garment slips between your fingers, the first story it tells isn’t in its silhouette or stitching — it’s in the whisper of texture against skin. That subtle ridge along the neckline, the gentle weave of a tag that feels broken-in from day one — this is where branding transcends logo placement and becomes tactile philosophy.In an age of sensory overload, luxury fashion is turning inward. The most discerning designers are embracing a new kind of statement: one made not through bold emblems, but through restraint. Enter the **woven label with washed finish and white print** — a quiet revolution stitched into the collar of tomorrow’s timeless wardrobe.

White-on-dark contrast achieved with precision dyeing and high-density weaving — clarity without compromise.

Minimalism, often mistaken for absence, is actually a form of presence carefully edited. High-end apparel brands are shifting away from flashy embroidery and plastic hangtags, opting instead for understated woven labels that speak volumes through subtlety. These aren’t afterthoughts — they’re deliberate design choices that signal confidence in craftsmanship. A small strip of fabric, placed discreetly at the side seam or nape, becomes a silent promise of quality.But what gives these labels their soul? It’s the **washed finish** — a process that transforms rigid threads into something supple, almost human. Unlike standard labels that stiffen over time, our washed woven labels undergo a specialized treatment that mimics years of wear right from the start. The result? A label that moves *with* the garment, never peeling, curling, or irritating the neck. Even after countless washes, the structure holds, the edges remain smooth, and the color stays true.And then there’s the paradox of **white printing**. On deep navy or charcoal fabrics, white ink should fade, crack, or ghost after repeated laundering. Yet here it persists — crisp, legible, unyielding. How? Through advanced pigment dispersion technology and tightly calibrated tension during weaving. Each thread is pre-dyed, not surface-printed, ensuring the lettering is woven *into* the fabric itself. This means no flaking, no smudging — just enduring clarity.

Microscopic weave patterns reveal the depth of craftsmanship — every thread aligned for strength and softness.

This evolution reflects a deeper shift in brand identity. Today’s consumer doesn’t need to be told a brand is luxurious — they want to *feel* it. The label becomes a private conversation between wearer and designer, a detail noticed only when sought. It’s anti-logomania at its most refined: a mark of belonging that doesn’t shout, but nods.Behind this elegance lies a rigorous journey. From raw yarn to final sew-in, each label survives industrial dye baths, tumbling wash cycles, and high-heat pressing. It must emerge flat, unwrinkled, and perfectly aligned — making it not just a branding tool, but a benchmark for production integrity. If the label fails, the garment doesn’t ship. That’s how seriously we take consistency.Designers of niche luxury lines have long known this secret. They reject glossy tags and metallic logos because authenticity can’t be laminated. Instead, they choose labels with a lived-in character — slightly softened fibers, matte finishes, off-white typography that feels organic rather than engineered. This "intentional imperfection" is what elevates a piece from mass-produced to heirloom-worthy.And let’s talk about touch. Neuroscience confirms that **texture shapes trust**. When fingertips trace the faint ridges of a finely woven label, the brain registers care, attention, value. This is sensory marketing at its most intimate — influencing perception before a single word is read. In a world of fast fashion noise, this quiet detail becomes unforgettable.Sustainability also threads its way into every aspect. Our labels use eco-friendly cellulose-based yarns, low-impact dyes, and water-efficient washing techniques. By eliminating plastic backing and minimizing chemical coatings, we reduce environmental load while enhancing comfort. This isn’t greenwashing — it’s rethinking branding from the fiber up.Finally, customization turns this functional element into a signature. Font weight, letter spacing, edge density, backing stiffness — every parameter is adjustable. One brand might choose a narrow tape with tight kerning for a modernist edge; another may opt for a wider band with vintage-inspired serif type. The possibilities are infinite, yet always restrained. Because true distinction doesn’t require volume.

Seam-integrated placement ensures longevity and comfort — branding as part of the fabric’s DNA.

Five years from now, when the jeans have faded and the sweater has been mended, that little label will still be there — softened by time, yes, but never silenced. Not flashy, not loud, but undeniably present. That’s the power of thoughtful design: it doesn’t demand attention. It earns loyalty.The future of premium apparel isn’t written in neon. It’s woven, gently, in cotton and conscience — one washed label at a time.

woven label washed label white print

View Detail >

Contact Supplier