In this highly competitive market environment, every detail of the product tells the image and story of the brand. And often the most easily overlooked small objects-labels, but play a vital role. A well-designed and excellent quality label can not only protect product information, but also give it uniqueness and high-end temperament.

Details Make or Break: Why Labels Are a Key Component of Brand Image

When consumers pick up a piece of clothing or open a box of gifts, the first thing they see is the small label. It is not only a functional identification tool, but also one of the ways to convey corporate values and quality commitment. Imagine if these widgets faded, worn or even fractured, which obviously has a negative impact on user trust. Therefore, it is very important to choose materials that are durable and beautiful at the same time.

From Material to Process: Reveal the Secret of high quality Woven Washed Label

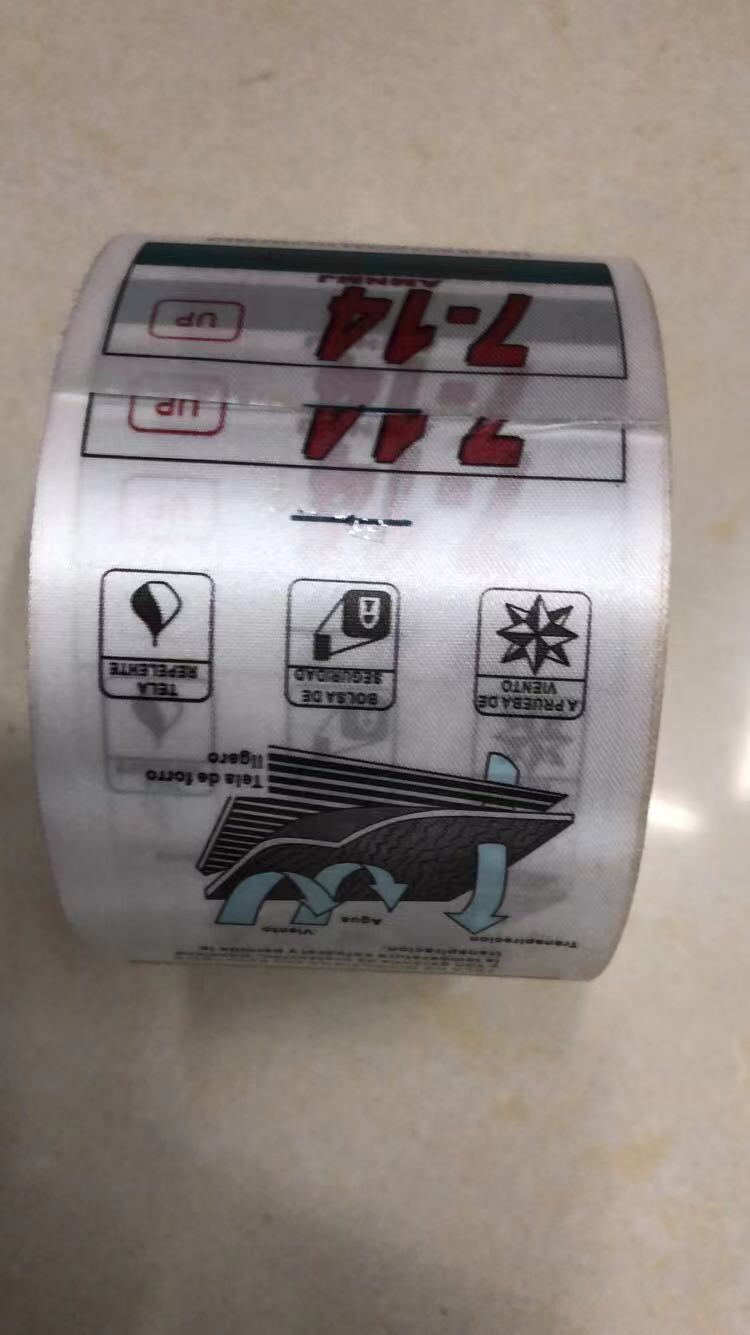

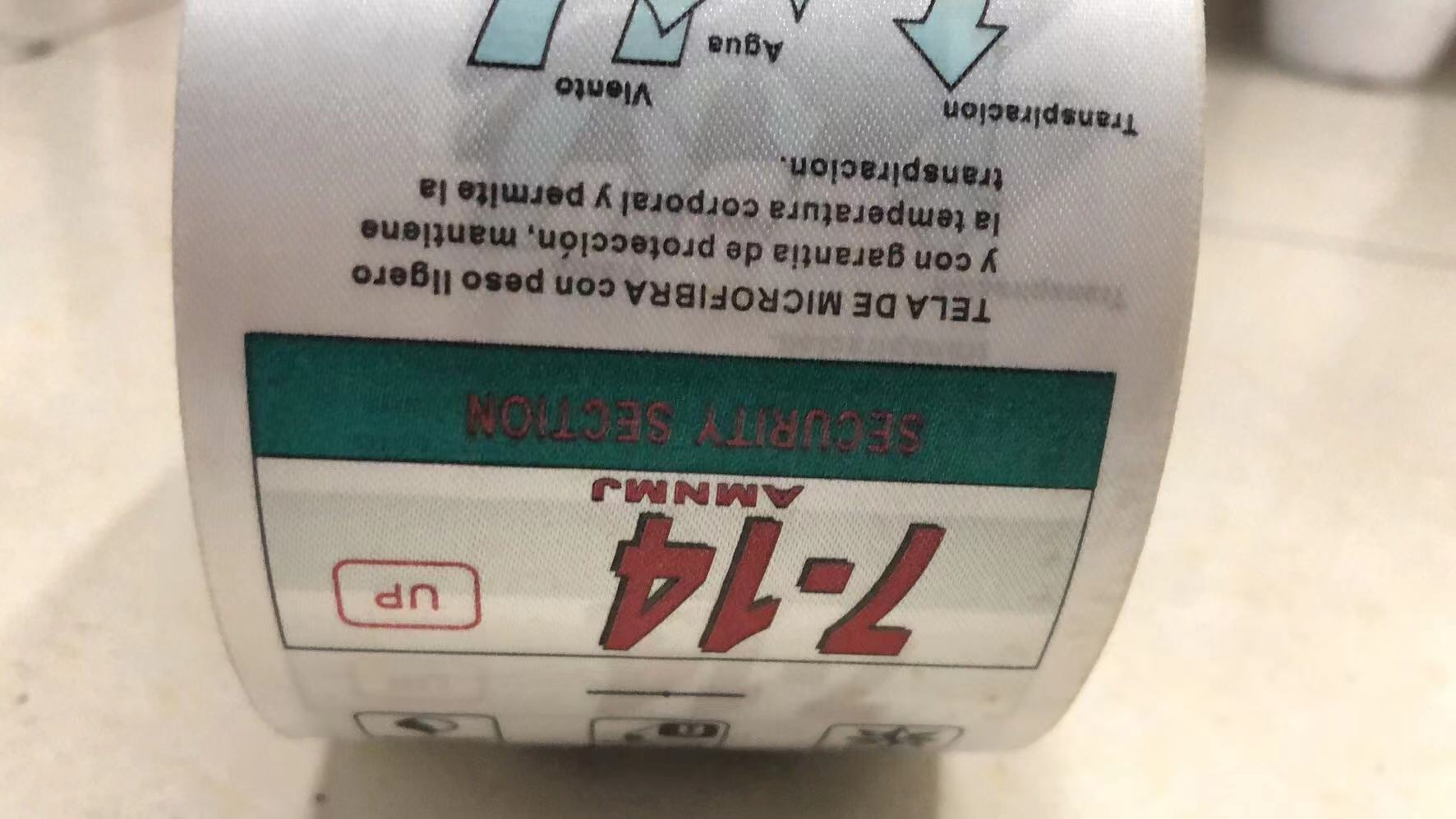

Our woven label washed label white print is a masterpiece based on this concept.

this type of label is made of high quality yarn woven, after special treatment with super tensile strength and soft feel characteristics. More importantly, they also retain the traditional embroidery-like delicate texture, and through high-temperature color fixation technology to ensure that the color lasting bright paint.

The charm of white printing: how to make label design more recognizable

In order to meet the needs of personalized customization, we have added exquisite pattern printing services on the pure white bottom. For example, the following figure shows a style with brand Logo logo: such a concise and lively design will not rob the main body of the product itself, but also make the overall packaging more colorful.

such a concise and lively design will not rob the main body of the product itself, but also make the overall packaging more colorful.

Durable and Clear: A Case Study of the Practical Application of Woven Washed Labels

Let's look at some real examples! A well-known clothing manufacturer has received a lot of positive feedback since switching to this new model. Especially those who often need to wash ironing maintenance of professional sportswear series performance is particularly prominent, even after many times of cleaning still maintain the original shape intact in good condition as first seen in general.

Exceeding Expectations: Customer Feedback Reveals the Business Value of Delicate Labels

Many partners said that since the introduction of this innovative solution, customer satisfaction has obviously improved and the repurchase rate has also increased significantly. "I used to worry about all kinds of problems after long-term use, but I didn't expect the effect to be so good!" A loyal fan is excited to say the truth. This shows that as long as you work hard to build every link, even if it is insignificant, it can bring unexpected benefits to the enterprise ~