Deciphering woven and washed labels: the secret of white printing

In today's competitive market, small labels often carry a huge mission. Especially for the pursuit of quality and characteristics of the brand, choose the right label can not only improve the product grade, but also convey the unique corporate culture and aesthetic concept. Today we are going to discuss two very representative label forms- woven label and washed label , and highlight the charm of the white printed version.

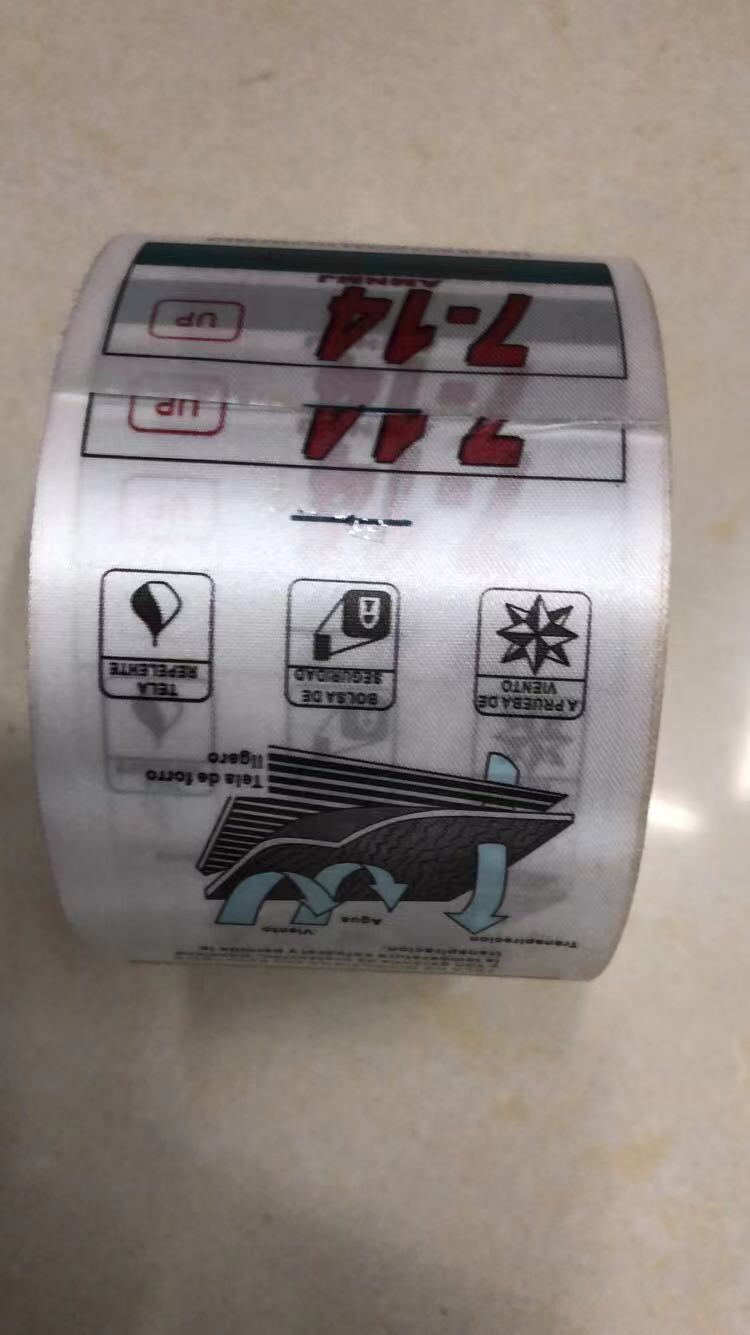

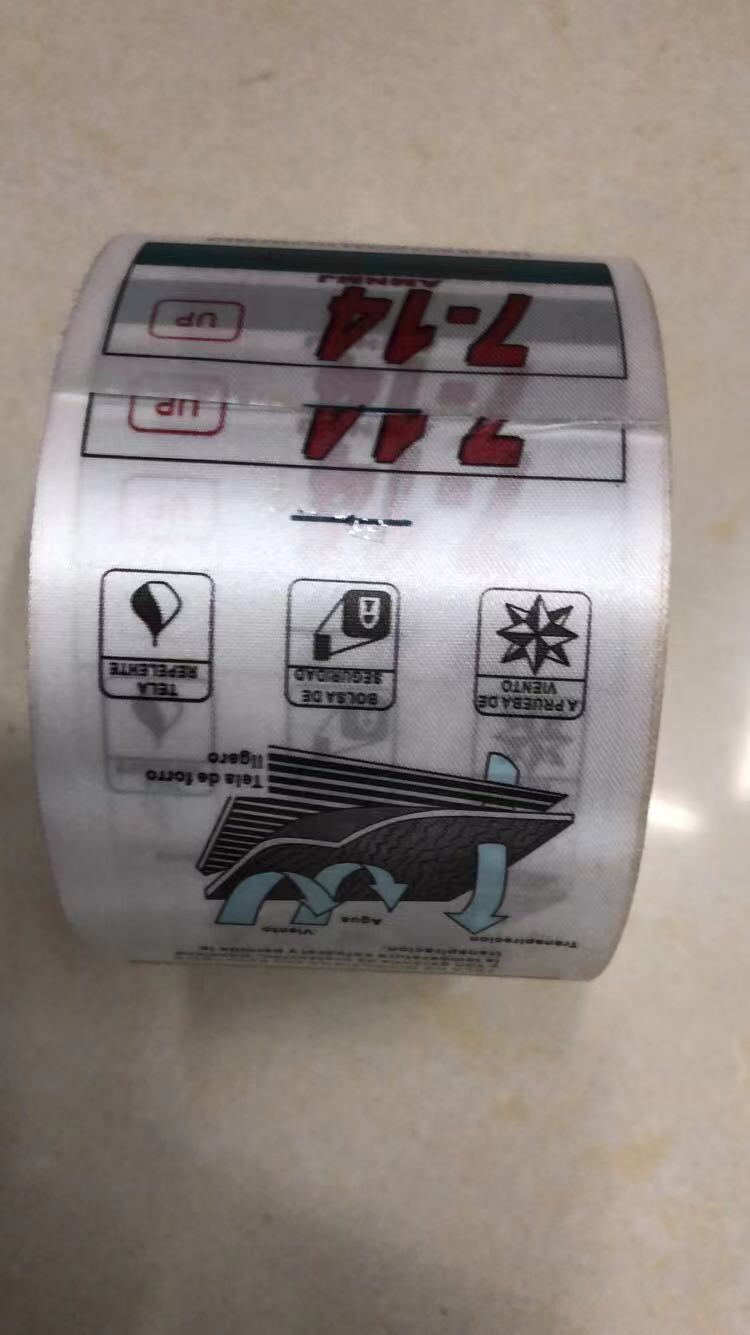

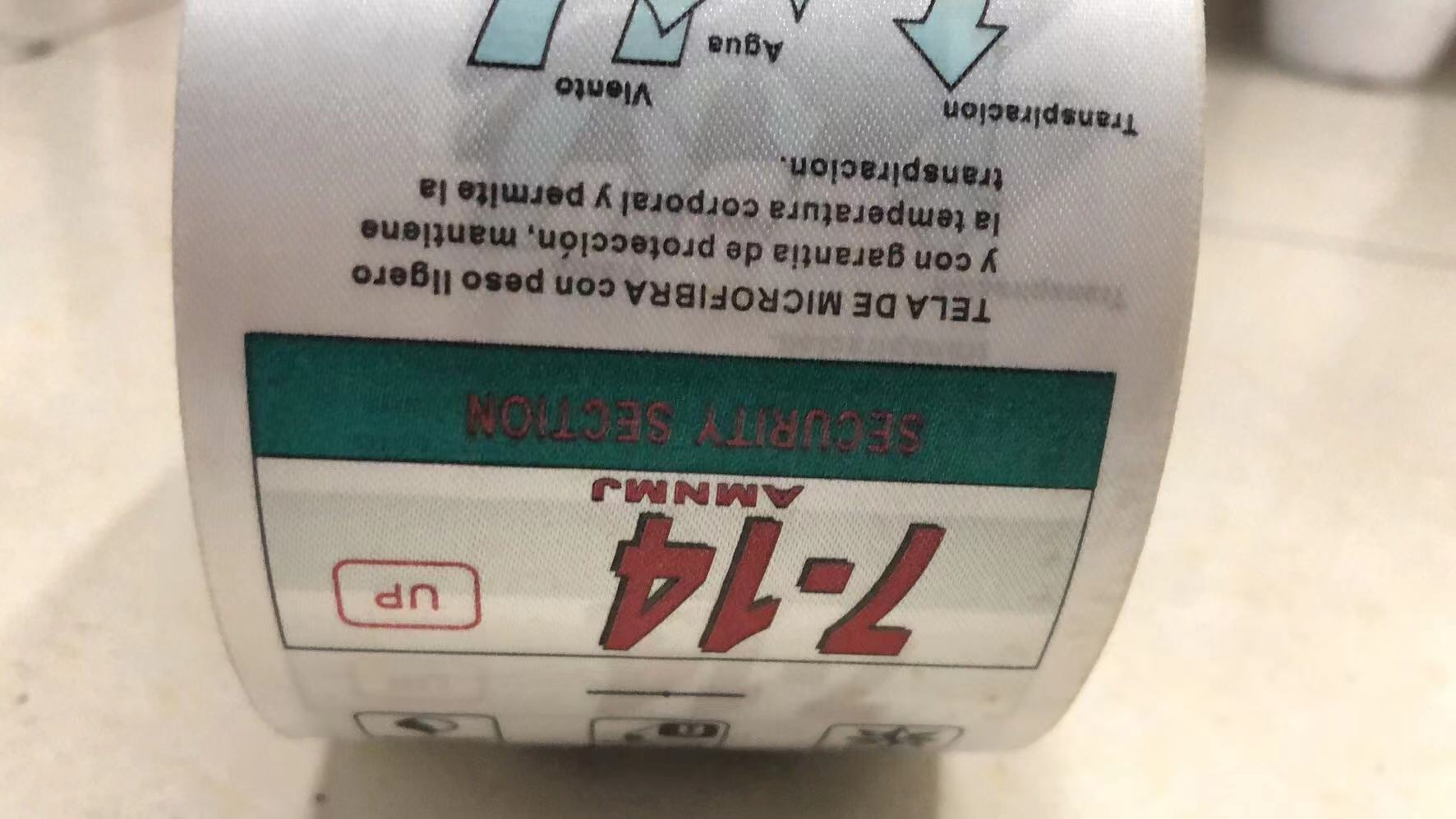

The main difference between the two lies in the production method and technical characteristics. Woven labels are usually completed by precision weaving technology, with high firmness and smooth touch; while washed labels are the products after special treatment, and the surface shows the effect of natural wear and tear, which is more retro style. Adding a well-designed white print on the basis of these two types injects a soul-like existence into each small piece of paper-not only an identification mark but also a part of the artwork. Whether it is simple and lively geometric graphics or delicate and exquisite plant patterns, they can inadvertently touch the heartstrings of consumers and let them feel the story and emotional connection behind the brand.

From Fiber to Finished Product: The Birth of Woven Labels

Every successful label is the result of countless small steps. Take woven labels as an example, from the initial selection of high-quality yarn to the final packaging before storage, the period has gone through dozens of processes. First of all, the raw materials are strictly screened, and only natural fibers such as high-quality cotton and linen that meet the standard specifications will be selected. The next step is to interweave these hairspring-like but tough things in a specific pattern to form a basic framework with a certain thickness that is not easy to deform. Then there is the crucial printing and dyeing stage, where it is not only necessary to ensure that the colors are bright and lasting, but also to ensure that every detail can be perfectly presented, especially when adding white printing.

It is worth mentioning that many manufacturers have begun to pay attention to the application of the concept of green environmental protection, using new eco-friendly pigments instead of traditional chemical synthetic substances, making the final products more healthy and safe. When all the preparatory work is completed, the next step is to send the processed semi-finished products into special equipment for high-temperature shaping and curing, so that those originally soft and fragile fabrics can become solid and reliable, durable and without losing the original texture and beauty. At this point, a complete woven label was announced.

The texture after years of precipitation: the unique flavor of the washed label

If the woven label represents the highly developed achievements of modern industrial civilization, then the washed label is undoubtedly more like a precious mark left in the long river of time. Behind its slightly rough but delicate feel, there is a complex, changeable and interesting production process. The first is the pre-impregnation stage, at which time the material to be treated is soaked with water for a period of time to reduce its hardness for subsequent operations; then it enters the main reaction zone-here is the most critical step to determine the final effect-by adding appropriate amounts of chemical additives such as softeners, bleach and enzyme preparations, etc, gradually decompose and destroy the close relationship between fiber molecules, so that the whole becomes more fluffy and soft, and at the same time it is easier to absorb other components to achieve the expected transformation purpose. Finally, after a series of auxiliary measures such as drying and finishing, we can get the finished product with unique temperament and appearance characteristics we have seen.

Because the whole process involves a variety of variables and parameter control requirements are extremely high, even two batches of goods from the same production line may have subtle differences, but this is one of the achievements of its charm. Every time people pick up a washed label with a faint fragrance and a little mottled trace as if telling the past years, there will always be an indescribable feeling in their hearts, both caring and nostalgic, and the desire to look forward to a better vision in the future.

Beyond Basic Functions: The Role and Significance of White Printing

In addition to being a simple information carrier, white printing also takes on more deep-seated tasks. On the one hand, it is an important part of the brand image, which can quickly and accurately establish customers' cognitive impression of a brand; on the other hand, it acts as a bridge of communication, expressing some abstract ideas and even cultural background stories with the help of text, language or pattern symbols, so that people can get inspiration from it. Especially in the context of the increasing popularity of customized services, more and more companies and designers tend to match their beloved works with unique and exclusive logos, not only to highlight the difference, but also to convey their own value propositions.

Specifically, when we see a